About Us

- 1

| Main Market | Air cooler, boiler |

|---|---|

| Brand | BOSHENG |

| Number of Employees | 51-100 People |

| Annual sales | US$5 Million - US$10 Million |

| Established in | 2018 |

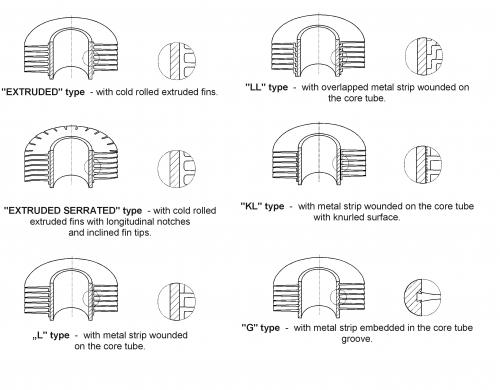

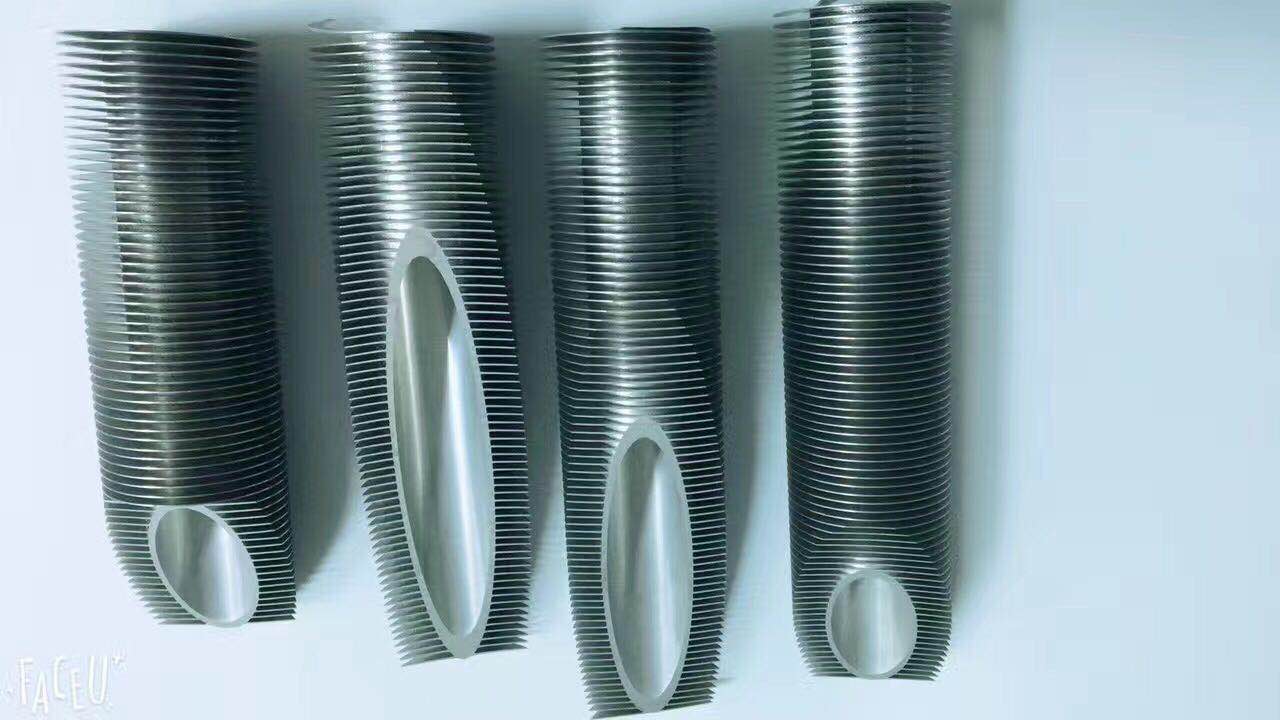

JIANGYIN BOSHENG THERMAL ENERGY TECHNOLOGY CO.,LTD is an experienced manufacturer of Mechanical-forming surface-extended thermal-transfer tubes(DR-Extruded/L-wrapped/LL-overlapped/KL-Knurled/G-Embedded aluminum/Copper fin tube) , Welding-forming surface-extended thermal-transfer tubes(Laser welding fin tube), Low Fin Tube etc..

Our direct clients are mostly the manufacturers of air cooler, fired heater, heat exchanger, marine boiler, economizer, power plant boiler, HRSG boiler, waste heat recovery unit, air heater etc,and our end users are mainly from these industrial sectors: power plant, refinery & petrochemical, Offshore & marine.

Our workshop size 60000 m2, employees around 100, machinery investment more than 1500000USD. And we are board member of China thermal&water engineering manufacturers association.

Our Finned tubing and finned pipe are used in heat exchangers, boiler economizers, coolers, and heaters.

1. Main production equipments

Four L/LL/KL /G fining lines, daily capacity around 2000 meters;

Thirteen extrusion fining lines, daily capacity around 6000 meters;

One laser welding fining lines, daily capacity around 2 tons,length《15meters

2. Mechanical-forming surface-extended thermal-transfer tubes

General Manufacturing Process:

Extruded Fins / Extruded serrated Fins

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process.

G Fin Tube (or Embedded Fin)

Finis embedded into the outer wall of the tube, but gives no surface protection. Ingeneral use for continuous process applications; ie refineries, petrochemical,fertilizer and gas plants.

Material: Carbon Steel, Copper Stainless Steel, Alloy, Aluminium

L Fin (or wrapped fin): with metal strip wounded on the core tube

The fin is wrapped around the tube and secured at each end. Gives some surface protection to thetube.

Used for moderate temperature cooling applications.

L-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system.

LL-type finned tube makes the trapezoidal cross-section forming by rolling combine closely with the heat flux density distribution size. The fins combine tightly with the tube,which makes the thermal efficiency higher and put an end to thermal resistance that brings by the non eliminate contact from segment gap of the string type finned tube.

1 Features:

The winding technology improves production efficiency and heat transfer, makes the average fin pitch and higher proportion between fins and tube. At the same time, the base tube can be protected from air erosion.

2 Application:

LL-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system.

The fin is wrapped around the tube with an overlapping foot and secured at each end.

Gives good surface protection to the tube. Used for moderate temperature coolingapplications.

KL Fin (or Knurled L fin): with metal strip wounded on the core tube with knurled suface

The fin is wrapped around the tube and the foot is rolled into the outer surfaceof the pre knurled tube and secured at each end. Gives good surface protectionto the tube and improved heat transfer compared to the L or LL type fin. Usedfor moderate temperature cool applications.

3. Low fin tube are mainly used in the condnsers and evaporators for air cooler and refrigerator, absorption refrigerator, oil cooler and other heat exchangers. And other industry such as coal power stations, nuclear power stations,boat heat exchangers, air cooler. Heat recovery system, dryers and heaters in chemical industries.

4. Welding-forming surface-extended thermal-transfer tubes

Laser welded fin tube

The fin strip is welded continuously and spirally wound onto bare tube. And the tube and fins are bonded together by using lase welding technique.

The Laser Welded Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

ERW HF spiral fin tube

The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using high frequency resistance welding technique.

The High Frequency Resistance Welded Helical Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

5. Inspection:

The inspector should carry out visual inspecton of the finished finned tubes at 10% random rate,the tubes are clean with no residue left from the finning process and no swarf between them.

The dimension inspection for finished finned tubes should be conducted in accordance with fin tube drawing. At 10% random rate, the inspection contents are overall length, finned length, bare end length, middle bare tube length, fin tube out diameter, fin heigh, fin thickness , fin pitch, all measureed values for dimension should beaccording to the drawing.

6.PACKING AND SHIPPING

All materials to be packed suitably for overseas shipment .

6.1.All tube ends shall be covered with cap or provided with other closurer.

6.2.Interior of packıng shall be lined with waterproof tar paper or equivalent material.

6.3.In case boards are used in loading of packing boxes and crates they shall be made of good

Quality pine wood or similiar.material having a minimum of knots,resinow pine wood shall not be

used.Dimensions of the boards shall be suıtable for the weight of goods to be enclosed.

6.4.Crates shall be adequately blocked and fastened to prevent movement of the of the goods relative to the box

while in transit or durıng loadıng and unloading.

6.5.Shipping containers shall be adequately reinforged with banding wires and/or steel straps of Proper size and

strength to prevent deformation and damage.

6.6.A waterproof envolope containing fully detailed packıng list prepared and showing purchase order and date

must be securely fastened to the inside of cases and or wired on the bundles or loose places

The fin types: